How

to build a Babington Oil Burner

last update

2007-09-15

So you want to make a Babington

burner?

(click

for high-resolution image)

Image is of a dual .0135"

Babington atomizer burning kerosene. Liquid fuel is delivered

through the 1/4" copper pipe at right, atomized by the two holes

blowing 30 PSI compressed air, and a flame is sustained on the left

side as long as the fuel flows. The excess fuel that pours over

the knob is caught by a steel funnel (in background) that guides it

into a sump.

Index

Overview

History

Fuels

burned

Making a Babington

Burner

Babington

Atomizer (the "nozzle")

Drilling

the Itty Bitty Hole

Compressed

Air/Pressurized Gas

Fuel

Supply

Burner

Tube

Fuel

Sump

Starting your

Babington

Pre-heating

the Oil

Adjust

the Compressed Air/Gas Flow

Constant

Fuel Flow

Constant

Air Flow

Additional

Information

Acknowledgements

The

(currently anemic) Babington Oil Burner FAQ is available

here.

Overview

A

Babington burner works like a whale's blow hole. Fuel flowing

over a curved creates a thin film due to surface tension. When

this film is pierce by a jet of air from a very small hole (typically

.010 inch), the fuel is not only atomized quite well, but also,

enough air is entrained by the atomized fuel to complete the

combustion, so there's no need for additional forced air for

combustion.

The huge advantage of Babington burners is that

there's no nozzle to clog: the fuel flows over the small air

hole, rather than through it, making this a very popular waste oil

burner. So long as the fuel pump can handle whatever is in the

liquid, be it metal shavings, french fry bits, or dirt, the burner

will continue working without fail. The tradeoff for this lack

of clogging is that you need to have a fuel sump that's located below

the atomizer nozzle.

Here's a picture of my very first

Babington - not very elegant, but it worked!

The

parts as seen are:

1) a Babington atomizer (the doorknob, in this

case). Normally, this is actually inside the burner tube, but I

pulled it out for demostration purposes.

2) source of compressed

air or gas (the 20lb propane container)

3) liquid fuel pump

(typically a gear oil pump) (not visible, but hooked to the copper

tubing)

4) burner tube (the old 100lb propane tank with the end

cut off). I mounted this on four legs to made a hand-height

hand warmer for an outdoor work area, and it worked great!

5) fuel

sump of some sort to catch the unburned fuel that runs over the

atomizer (the cut-off end of the old 100 lb propane tank)

6)

splash guard - part played by that chunk of H-beam, otherwise fuel

splashes everywhere.

Here's an end view of the Babington while

running (looking up cut-out propane tank):

(click

for higher resolution image)

That's a cinderblock just

downstream of the burner that greatly assisted in keeping the flame

running. Also, note that there's no smoke! When

everything is running properly, there's just wavy hot air as

exhaust.

You can also kind of see the gear oil pump

floating in midair beneath the burner tube It's drawing fuel

from the upper left hand corner of the sump, pumping it around the

propane tank twice (to preheat the fuel), and then pouring it over

the doorknob where the fuel gets atomized.

Things odd about

this setup include:

1) there's no propane regulator, and the

propane flow was difficult to control just using the tank knob

2)

I was making a dual-fuel burner (kerosene/glycerol), hence the "T"

in the galvanized propane tubing and one capped end.

Someday...

3) since this was a test setup, there's no fuel tank -

I just filled up the sump and ran off that fuel

History

Patent

# 3,425,058

was granted to Robert S. Babington in 1969. It has expired, and

the burner design is now in the public domain.

Patent #

4,155,700

was granted to Robert S. Babington in 1979. It details a

dual-atomizer Babington burner that uses forced air for combustion.

It looks exactly like Babington

Technology's Airtronics(r) burner (fancy that), which was

primarily marketed for military food preparation and runs off of

diesel fuel. This patent has also expired.

John

Archibald has really picked up where Mr. Babington left off, and is

the father of the home-built Babington. He has written at length

about the Babington in the Wastewatts group over the past few years,

so if you're going to read the archives from just one person, he's

the one.

Fuels

Due

to the excellent atomization, Babington burners will burn many heavy

and waste oils such as:

diesel (~140,000 BTU/gallon)

biodiesel (~130,000 BTU/gallon)

kerosene (~140,000 BTU/gallon)

waste transmission / motor oil

(~150,000 BTU/gallon)

waste vegetable oil (WVO) (~130,000 BTU/gallon)

(all the BTU values seem to change +/- 5% based on source and quality

- take these numbers for comparison purposes only)

The only

difference is that the preheat temperature, and compressed gas PSI,

will change for optimum burning of different fuels.

I estimate

that a single .010" hole consumes about 1/3 gallon of liquid

fuel per hour. This works out to about an 40,000 BTU heater

with WVO. To increase the output of the burner, drill another

hole 1/4" from the original hole and you will double your fuel

usage & heat output. (If the hole is closer than 1/4",

the streams will overlap and it won't burn quite as well)

Warning:

do not attempt to burn gasoline, methanol, or an other

volatile fuel with a Babington burner! The whole sump as well

as the atomizer can catch fire explosively, and while that can be

exciting, that's not not the goal here. :) I once burned some

biodiesel that still had some methanol left in it, and yes, it was

quite exciting, so I'm speaking from experience here.

Making

a Babington Burner

Making

a Babington Burner is faily simple, but there are a number of pieces

that have to work together in order to do so.

Also, please

note that I'm not a mechanical engineer (I'm a software engineer,

actually), and playing with combustible fuels, while fun, can be

rather dangerous. I highly recommend keeping a fire

extinguisher close to your Babington burner at all times, especially

while you're tinkering with it.

Babington Atomizer

(the "nozzle")

The fuel needs to flow over a

curved surface in order to work properly.

Complete

Babington nozzles can be purchased from Andy Mahoney at Homebrew

Power, but what's the fun in that?

The professional-looking DIY method is to just buy a hollow steel

ball. Any size ball, made of any common metal, in any

reasonable diameter is available from

J. G. Braun Co. • 8145

River Drive • Morton Grove, IL 60053053-2645

800-323-4072 •

847-663-9300 • Fax: 847-663-0667 • info@jgbraun.com

A 3"

hollow steel ball is about $10.50 (but with $75 minimum order) from

RB

Wagner

However, some (most?) people use keyless interior

doorknobs. Cut off the shaft of a knob with a sabre saw, then

braze or JB Weld a copper SLIP x FPT adapter onto the shaft,

and screw into your compressed gas source. Make sure you clean

both surfaces with a solvent first, and rough up the surfaces with a

wire brush/wheel or sandpaper. I have had some luck in this

department, but a couple of failed attempts, too:

(click

for larger picture)

I tried to braze both of them, but the

doorknob on the left just wouldn't seal (it was actually a pro I

asked to help me that blew a hole through it!). The knob on the

right was purchased new, but I couldn't get anything to adhere to,

even after thoroughly roughing up the surface with a wire brush

wheel. A very old doorknob from a salvage yard, probably made

pure brass, worked just fine, though.

Alternately, several

folks have successfully used brass end caps with a groove cut into

them.

What size atomizer is right for you? Dave Brown

says:

"I have tried both large and small balls.

The large balls were door knobs (interior, keyless, lockless) drilled

with 0.010" holes (one hole and two holes). The small

balls were brass end caps (flare fittings) with 0.0135" hole

(one only), with and without the groove.

I don't think it's as

simple as comparing ball sizes, as other factors such as dirt in the

fuel and delivery system play as big a roll.

The overriding

goal or principle, regardless of size, is that optimum atomization of

the oil requires a thin film of oil over the ball at the point where

the pressurized air exits the ball. So, given that basic

premise, my observations are as follows:

BIG BALLS: If

your method of delivering the oil to the ball isn't precise, then the

large ball has a decided advantage in that it will accommodate a

higher flow rate and still deliver a thin film of oil to the air

stream. Excess oil runs off and is simply drained to the

sump/oil tank and recirculated. Since this oil has been

pre-heated, it warms and lowers the viscosity of the oil in the sump.

There is more latitude in fuel flow rates while continuing to deliver

the desired thin film of oil to the air stream. Seeing as

consistent fuel delivery seems to be a constant headache, at least

according to the history of posts to this list, the large ball is

more forgiving. It seems to me that it tolerates fluctuations

in fuel flow rather well. Last, but not least, is that the

larger openings in the fuel flow controls will tolerate dirtier oil

and larger particle size of contaminates. In other words

the fuel lines and valves won't clog as easy. The need to have

fairly well filtered waste oil or drawing well away from sediment is

moot.

LITTLE BALLS: They sure do work just fine and

deliver the oil to the air stream as required. But they are

different from the big balls. I used brass end caps (3/4"

and 5/8" size). They come with a flat end which makes

locating the center and drilling easier (to an extent). I then

chucked mine into a drill press and while they spun I used an angle

grinder then some fine sand paper to round off the flat area. I

found out that you must

be careful because the caps aren't as

thick as you think they are. It's easy to take too much metal

off and ruin the ball. Now, given the size of the ball I found

that you have to control your fuel delivery much more. It is

easy to flood and overpower the air stream. Even a little bit

of excess flooding can result in a deterioration of droplet size in

the fuel fog, which in turn affects combustion. I found that

you really have to control the fuel delivery to the point of very

little runoff or no runoff at all. This has it's own set of

plusses and minuses. If you can get manage to achieve zero

runoff then the plumbing for the runoff return line is taken away.

But, you should probably have it plumbed for runoff anyway so you

don't create a puddle of overflow in the burner. Since you are

targeting such narrow control over the fuel delivery (i.e. needle

valves or

similar) you have to be concerned with particulates in

the fuel that could easily build up in the valve and create a

blockage. So, here again I've concluded that the fuel delivery

method and level of filtration is the primary determining factor as

to which size ball you really need."

Drilling

the Itty Bitty Hole

For the

atomizer to work properly, the hole for the compressed gas flow needs

to be very, very small. .010" is recommended, though you

can use .0135" or even up to .0200". Any bigger than

that, and the droplet size gets too big, and results in poor

atomization.

Q: where do I get .010 drill bits?

A: What you

want are re-sharpened drill bits that are out of spec (too short)

from the drilling of circuit boards. They are solid carbide with 1/8"

shanks.

A source for small quantities of resharpened bits is

Drill Bit City

5 packs of .0135" bits: $5.75

5 pack of

.0100" bits: $7.15

These bits are so small that if you

look at them sideways, they'll break. Ever break a 1/16"

drill bit? These bits are less than 3% the size of a 1/16"

bit. Using a high speed micro drill (like a Dremel tool) is

highly recommended. Also, Dremel drill presses are inexpensive

(about $40),

and make it easy to drill the hole. Just make sure you clamp

your piece down tightly, and drill very, very slowly. I've

heard that it's possible to drill the hole freehand if you're going

through a very thin-wall doorknob, but I broke several bits trying

this, and don't recommend it.

To double the heat output, just

drill two holes about 1/4" apart. Note that in my image

above of the dual .0135 hole Babington atomizer, the holes are too

closely placed - they should be about 1/4" apart instead of the

1/16" apart as shown. The two fuel sprays collide and form

larger droplets, which isn't ideal, but still works.

Compressed

Air/Pressurized Gas

Using compressed air for

atomization is cheap, and works great. Highly recommended.

From this orifice air flow chart,

we can estimate that a single .010 hole Babington should use

approximately 4 cubic feet/hour at 30 PSI (a .010 hole should about

40% the air that a 1/64 hole uses).

Since

the air needed is quite low, someone on Wastewatts recommended "some

refrigeration compressors, even possibly an aquarium air

pump."

Possible sources for suplus (read: cheap) air

compressors:

www.surpluscenter.com

http://surpluscityliquidators.com/

If

you don't have an air compressor handy, propane works fine, too.

Expect to use about 0.1 gallons of propane/hour of runtime for each

.0135 hole that you drill. Since 0.1 gallons of propane =

4000 BTU, and a one hole Babington uses about 2/3 gallon of fuel per

hour (~80k BTU), the propane component of the heating is less than 5%

of the total heating mixture.

Propane pressure seems to make

the mixture a little rich, and you have to care about propane leaks,

which is annoying.

Fuel Supply

Fuel

Pump: A gear oil pump is highly recommended. Again, try the

following places for cheap surplus oil and fuel

pumps:

www.surpluscenter.com

http://surpluscityliquidators.com/

I

got a 12V gear oil pump that worked great for $20 from Surplus

Center.

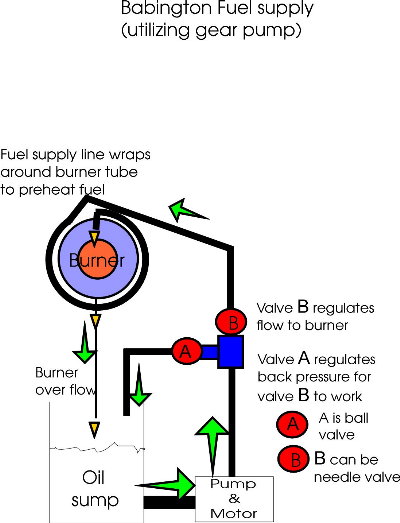

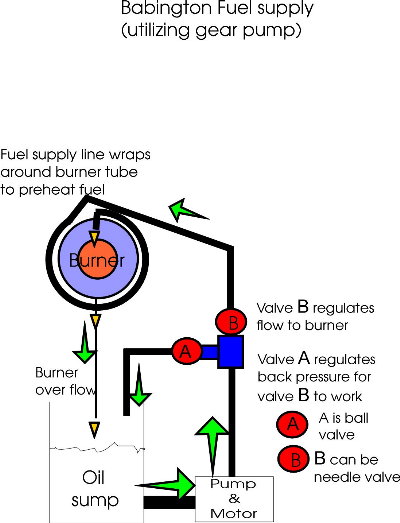

Dave Brown made a nice diagram of how the fuel supply

pump is hooked up in the system:

(click

for larger image)

Gravity Feed: Generally, this is a

bit more difficult because as the liquid level in the source

container drops, the fuel pressure drops, and hence the fuel flow

over the atomizer changes. Some people have gotten it to work

just fine, but using a fuel pump is easier.

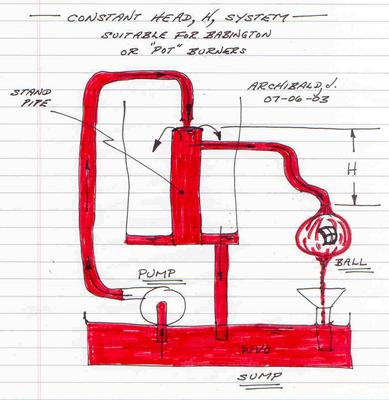

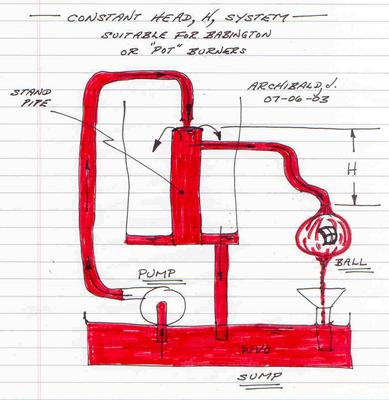

Constant Head

System: Whether you're having problems with an oil pump that

pumps at too high of a pressure, or a inconsistent fuel pressure due

to gravity feed, one option to guarantee constant fuel flow is to use

a constant head system like this one designed by John

Archibald:

I

think this is one of the most elegant plumbing systems. So long

as the volume of fuel delivered by the pump is sufficient for the

burner, it doesn't matter what kind of pump you have, how much fuel

it's delivering, or the delivered fuel pressure. This will

convert it into a low volume, low pressure delivery system, which is

what you want in this case (high pressure will splatter fuel off the

atomizing ball).

Regardless of how you achieve it, a constant

fuel flow is necessary. If the flow varies at all, the flame

can start oscillating and put itself out.

Burner

Tube

John Archibald recommends

a 6" x 3' tube. Personally, I've had pretty good luck with

a 3" ID by 3' long pipe so long as it is a single

hole.010" atomizer. Heavy wall pipe is better, as it holds

more heat in, making for better combustion.

I've also managed

to get a dual hole atomizer working with an old 12" diameter

propane tank (see above pictures). However, when you use a

larger diameter pipe, the flame tends to be unstable once the burner

tube heats up. After watching it go out a few dozen times, my

theory is that the fuel & air mixture expands so much that it

creates a pressurized section in the pipe that is strong enough to

overcome the air jet coming out of the Babington nozzle, and this

leads to a burner oscillation that will put the flame out. It's

a distictive sound that you'll get to know well until you get it

fixed. How I overcame this problem with the large diameter pipe

was to install an inner combustion pipe, 3" x 12", to

channel the flame and assist in air entrainment.

You should

also block off most of the back of the burner tube, ideally with an

adjustable flue of some sort. I just stuck a cinderblock

downstream in the pipe (visible in the pictures above) Iit

retards the airflow away from the atomizer, reducing the chance of it

blowing out, as well as helping it to stay hot. It was

also quite necessary when running in a windy location.

Also,

drilling four holes in the burner tube can be quite helpful.

Dave Brown says:

"These holes need to be placed in

opposing pairs. One pair left and right on the pipe and

just slightly (i.e. about 1" plus or minus) forward of the front

tip of the nozzle/ball. The next set should be top and bottom

on the pipe and just slightly (i.e. about 1" plus or minus)

forward of the first set of holes. This does more than simply

admit combustion air. It disturbs the shape of the fuel

cone and improves the air/fuel mix in the process, thus improving

combustion efficiency and propagation. More holes may help, but

if there are too many or admit too much air at low velocity then it

does little to help combustion. Also, too much air means that

you have to also heat that air and send it up the chimney rather than

into the walls of the pipe and hence into the space to be heated ...

your "shop", as it were. I do not know if there is

any information available regarding how much air or hole area is

best. In my case, using a 6" diameter pipe, I drilled 3/8"

(9.5mm) diameter holes and they seem to do the job just fine."

Fuel

Sump

This catches the fuel that

runs over the atomizer, but is not atomized. I used the bottom

part of an old 20 lb propane cannister as my sump, and used a piece

of sheet metal rolled into a cone to keep the fuel from splashing

into the sump (this was an improvement from the small H-beam in the

photo above). I should have made the sump deeper than the 3

inches it is: the next version will be an old 20 lb propane tank with

the top cut off, which should hold about 12" deep and hold 3

gallons. This will be my primary fuel source, and when burning

1 gallon per hour, will act as a 3-hour timer on the burner - just

about right for my purposes (YMMV).

Starting

Your Babington Burner (and how to keep the flame from going

out)

Turn on the gear oil pump, turn on the air

compressor, and then light the atomized liquid fuel with a small

propane torch or butane jet lighter. Watch it burn for a second

or two and then, most likely, go out. This begs the question:

how do you keep it lit?

Pre-heating the

Oil

Pre-heating the oil before it pours over the

atomizer is pretty much required to keep your Babington lit.

The simplest way to do this is just make a couple of wraps around

your burner tube with 1/4" copper tubing before delivering the

fuel to the gear oil pump. Adjust the number of wraps until the

fuel is preheated to an adequate temperature. About 140 degrees

F seems to be about right for kerosene or diesel, and 160-180 F for

any heavier oils. If you get any hotter, you may start causing

in-line gasification, and you then risk building up crud in the line

and plugging it up.

Warning: if you coil your supply

fuel line around your combustion tube for preheating, then if your

fuel supply runs out or the pump stops, the fuel in your fuel line

will heat up to the temperature of the burner (about 1200 degrees F),

which is above the flashpoint for most fuels. If your fuel flow

stops for more than a few seconds, is it safest to wait 10-15 minutes

until everything cools, then try restart the burner. I once didn't

wait, and had superheated oil flow into my sump and start it on fire

- not good!

However, using fuel line wraps around the burner

only helps preheat the fuel _after_ the burner is running: it doesn't

help when you first start up your burner. Possible solutions

include:

use a propane torch to manually

heat the fuel tube until the burner is burning good and hot. Easiest

to get started with.

crock pot: keep water in it and

have a copper coil immersed in it. The oil flows through the

coil on it's way to the Bab ball.

old coffee maker: good for 5

minute preheat

submerged electric heater: make sure to use a timer to make

it easy on yourself - no need to have the electric heater on after

the heater tube is warmed up!

Adjust the Compressed Air/Gas Flow

20-30

PSI seems to be about the right range for good combustion, 30 PSI for

startup, 20-odd PSI for running.

If the flame is blown down

the tube before igniting, lower the gas pressure. If it's

already too low, you may be using too small of a tube (a 3" tube

is too small for a dual hole atomizer). Also, did you remember

to put a flue or otherwise restrict the flow out the end of the

burner tube?

If the flame is yellow and sooty, increase

the gas pressure. The mixture is too rich, and needs more

air.

For feedback and comparison purposes, it helps to have an

air pressure gauge in the system. These can be found as most

any big box hardware store in the air tools section. They

should cost about $10 each.

Constant Fuel

Flow - oscillations in the

flame front can be caused by inconsistent fuel flow over the

atomizer. See the "Fuel Supply" section for more

information on avoiding this problem.

Constant

Air Flow

If, after burning for a few minutes, the

Babington goes out when the flame "runs away" down the

burner tube, you may need to install a flue to control the airflow.

This usually happens if you have a vertical exhaust vent.

What's probably happening is that the vent is heating up, increasing

the flow of air through the tube, and eventually blowing out the

burner with too much air.

Still having problems?

Are

you using a .010" hole? Larger holes create a larger

droplet size, which are harder to light and sustain.

Additional

Information

Hundreds of photos of

working Babington burners can be found in the Wastewatts photo

gallery:

http://photos.groups.yahoo.com/group/wastewatts/lst

Here's

a nice Babington made from 1.5"

pipe:

http://dragoneagle.50megs.com/metalworking/babington.html

The

(currently quite anemic) Babington Oil Burner FAQ is available

here.

There is a

Babington Burner-specific email list:, altfuelbabington, that is an

offshoot of the altfuelfurnace

group.

http://dir.groups.yahoo.com/group/altfuelbabington/

To

ask questions of knowledgeable people, join the Wastewatts discussion

group on Yahoo Groups. Search the message archives for answers

to most any Babington-related question (and I mean most any question

- they've all been asked before).

The original page where I

learned how to make a Babington burner can be found

here:

http://www.green-trust.org/2000/biofuel/babington/default.htm

Finally,

here's a page about Babington burners from the folks that know

best:

http://www.babingtontechnology.com/technology/index.html

Acknowledgements

Robert

Babington

John Archibald - most of this document is taken from

information he's collected and written about in the Wastewatts

group

Dave Brown - some passages were lifted verbatim from his

posts to Wastewatts

Steve Spence - for hosting the green-trust

site where I first learned about the Babington

Nick Fankhauser and

HC for providing good feedback

All the rest of the folks on

Wastewatts for their insights and encouragement.

(c)

2004-2007, 2012 Tom McCarty (email aip at the domain

aipengineering.com)

All

text and images in this web page are licensed under a Creative

Commons License.

Some rights are reserved.